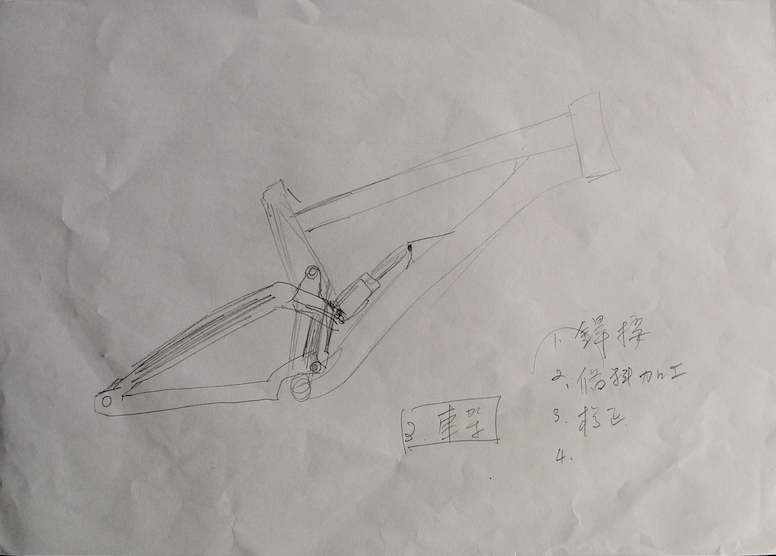

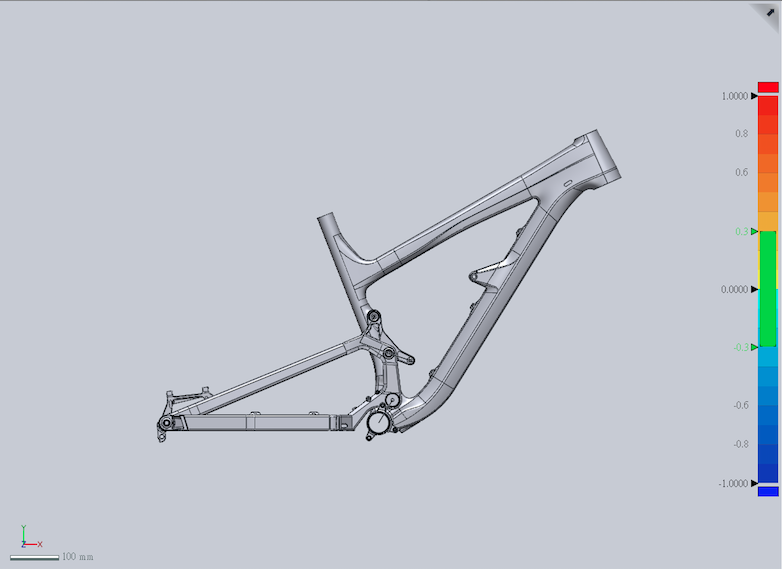

STARTING WITH AN idea to 3D model to physical frame to test ride

A product idea can be a sketch on a napkin, or a 3D rendering on your laptop. The next step is to find a manufacturer. For some, the far-east intimidates them, the high minimum ordering quantity, unknown quality, communication barrier, and concerns about labor's working environment.

This is where we come in. Having our team physically at the manufacturer's site ensures you get punctual delivery, good quality, no miscommunication in product development, and most importantly, making sure your product is produced in a socially responsible factory where no workers are mistreated.

OEM work is the soul of Leeche International. We pride ourselves in setting up the best supply chain for your aspiring bike brand.

We have a very resourceful pool of frame suppliers that does work for Trek, Devinci, Ritchey, Yeti, Canyon, YT Industries, Jeff Jones, DMR, Genesis, Transition, Salsa, and Surly just to name a few. We work with the finest steel, titanium, aluminum suspension, and carbon frame manufacturer in Asia.

Below are our primary services. We also accommodate special request.

Complete bike assembly service

- Assist with creation of BOM(bill of material)

- Spec sourcing

- Component compatibility check

Frame development

- Assist with engineering

- Help transform a product idea(sketch) into a manufacturable drawing package

- Assist in ensuring frame meet international testing standard(EN, ISO)

Components development

- Assist with engineering

- Help transform the product idea(sketch) into a manufacturable drawing package

- Rims, cockpit, tires, cranks, hubs, the list is endless

PROJECT MANAGeMENT

- Establish the timeline for product development project

- Actively manage the product development team(customer and supplier) to hit the deadlines

SOFT GOODS DEVELOPMENT

- Help develop pannier, handlebar bag, dry bag, and frame bag

PRODUCTION DELIVERY SUPERVISION

- Ensure the suppliers deliver on time

- Coordinate frame/fork/paint shop/parts delivery for complete bike assembly

- Use forecast to manage planned production

LOGISTICS

- Consolidation of goods

- International distribution logistics and warehousing

QUALITY ASSURANCE

- Frame, fork, and parts geometrical inspection

- Complete bike inspection

- Production batch lab testing

PACKAGING DESIGN

- Assist with material sourcing

- Assist with box design

GRAPHICS CAPABILITY

- Have a diverse pool of paint suppliers to choose from based on the frame material, paint type and price

- On-site quality control

The area we particular excel in is managing the upper supply chain to maximize flexibility. Instead of relying on the tier 1 supplier to source your raw material. We can help you go directly to the source to create a competitive edge.

- For aluminum tubes, we have our own supply chain for tube butting, tube hydro-forming and mechanical forming.

- For aluminum frame parts, we have our own supply chain for forging, CNC milling and lathing, as well as fine blanking.

- For cromoly steel, stainless, and titanium tubes, we have our own supply chain for tube butting, heat treatment, and mechanical forming.

- For cromoly steel, stainless, and titanium frame parts, we have our own supply chain for investment casting, forging, and metal injection molding(MIM).

We are ready to bring your ideas to life. Contact us for more information